As part of our series celebrating our wonderful business partners we spoke with Blackman & White, the UK’s leading manufacturer of industrial laser and knife cutting systems, renowned for textile and composite applications. Managing Director Alex White discusses the cutting solutions best suited for marine fabrics and sailcloth, how their machines maintain precision with laminated and UV-coated materials, and how software integration improves nesting efficiency and reduces waste.

Can you introduce us to yourselves and what you do at Blackman and White?

I’m Alex White, Managing Director of Blackman & White.

Blackman & White is the UK market leading manufacturer of industrial laser and knife cutting solutions. We focus on the textile and non-metallic applications which gives us access to a whole world of composite advanced materials, marine textiles and apparel applications. Our machines are designed and built to be user friendly, offer value for money to our customers and range from entry level to fully automated cutting systems.

Which cutting systems do you recommend for marine fabrics and sailcloth, and why?

For marine fabrics, we often recommend flatbed systems. They allow the material to be laid flat for inspection, ensure stability during cutting and make it easy to switch between different fabrics which is important for customers who frequently handle multiple material types.

For sailcloth, a laser cutter is typically preferred because it produces a clean, sealed edge. Without a laser, a secondary process, such as using a hot knife, is usually needed to seal the edges.

At Dolphin Sails we have specific requirements: high precision, strong material handling, and secure quality control for UV-coated fabrics and laminated sailcloth. How do your machines maintain precision when cutting coated or laminated materials?

We offer both conveyorised and flatbed laser cutters and can supply the Genesis range of cutting tables either as a static table (up to 30 metres long) or as a conveyor table (typically between 3 and 5 metres in length.) Conveyor systems allow cutting of jobs that are longer than the table and provide improved material efficiency, though they do not allow inspection for material flaws during the cutting process.

The Dolphin machine is designed to handle materials up to 3 metres wide and features interchangeable laser and knife cutting options. For materials unsuitable for laser cutting- such as PVC, which can burn and produce fumes -a knife cutter is preferable. Other materials, like carbon fibre, also benefit from knife cutting due to their high melting points, which make clean laser cutting difficult.

How does your equipment or software help reduce fabric waste and improve nesting efficiency?

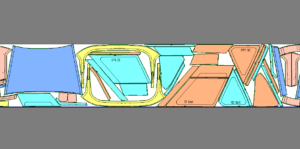

Material nesting is the automated process of arranging 2D shapes efficiently on your material. This is critical when working with high-value materials. Traditionally done by hand, nesting software now allows much faster layout generation and optimises material usage by testing multiple arrangements. With material costs exceeding £30 per square metre, the efficiency gains from nesting software typically offset its cost within the first year.

Do your machines integrate easily with sail-design and CAD/CAM software?

Our machines integrate seamlessly with a wide range of CAD/CAM software. In the marine industry, Rhino 3D is often the software of choice. Rhino is a full 3D CAD platform well-suited for designing large-scale structures. It offers numerous plugins that allow materials to be “relaxed” from 3D forms into 2D patterns. Rhino also supports handling large models, full rendering and importing graphics, enabling a complete visual representation of the finished structure.

What makes your machines stand out in terms of reliability, upgrades, and long-term value?

One key feature that sets our machines apart is their seamless integration with Rhino via a dedicated system plugin. This allows users to handle the full workflow directly within Rhino, including panel layout, nesting, numbering, curve smoothing and even inkjet marking of part numbers. This therefore eliminates the need to switch between multiple software packages. By streamlining design and machine control in a single environment, our machines offer enhanced reliability, easier upgrades, and long-term value, saving time and reducing potential errors throughout the production process.

How important is it to you that your machines are British designed and built, and how does that benefit UK manufacturers like us?

Blackman & White was founded by my father in 1964 with a strong commitment to keeping manufacturing jobs in the UK. He believed it was essential for the country to maintain its manufacturing capabilities. While the UK has seen declines in sectors like automotive, aviation, and parts of aerospace, it remains a critical supplier for these industries. Ensuring that our machines are British-designed and built supports local industry, preserves manufacturing expertise, and strengthens the UK’s resilience—an issue highlighted during COVID when the lack of domestic production for key components left the country exposed.

To find out more about Blackman and White visit their website

Or to enquire about getting your new set of sails and covers in time for next years sailing season Follow the link below.